792-XSLIDE

The gear tray is made of white powder coated steel sheet according to Zhaga standards. On request customisation is possible.

The diffusing part of the profile is made of UV stabilized opalised material, specially developed for LED applications. This ensures among others a well-balanced light distribution and the elimination of glare.

A. the pull-out (sliding) tray accelerates the electrical connection easily without disassembling the luminaire.

B. The glued end caps are locked up hermetically. After opening it the connector tray is accessible.

Ways of installing

1. With strengthened stainless steel mounting brackets. They are easy to install onto the wall or ceiling.

2. suspension on chains or rope with stainless steel suspension brackets mounted with hooks.

The mounting brackets can be positioned freely on the housing.

The gear tray is made of white powder coated steel sheet according to Zhaga standards. On request customisation is possible.

The diffusing part of the profile is made of UV stabilized opalised material, specially developed for LED applications. This ensures among others a well-balanced light distribution and the elimination of glare.

A. the pull-out (sliding) tray accelerates the electrical connection easily without disassembling the luminaire.

B. The glued end caps are locked up hermetically. After opening it the connector tray is accessible.

Ways of installing

1. With strengthened stainless steel mounting brackets. They are easy to install onto the wall or ceiling.

2. suspension on chains or rope with stainless steel suspension brackets mounted with hooks.

Ways of installing

The mounting brackets can be positioned freely on the housing.PARAMETERS

Built-in

Options

Further options

On request

TECHNICAL DESCRIPTION

792-XSLIDE

Industrial dust and waterproof luminaires with LED modules

YOUR MAIN BENEFITS

Comfortable and quick installation without disassembling the luminaire Extruded profile with outstanding light transmissivity Slender design and clean impression, specially developed for LED applications Glued end caps with pull-out (sliding) tray for easy connection Economical and cost-efficient

FIELD OF APPLICATION

Thanks to the construction principles of gasket, end caps and the extruded profile our LED fixtures ensure a high grade of protection (IP 65) against dust, contamination, and water permeation. In accordance with their IP grade they can be widely used to illuminate spaces with dusty, humid environment. When using outdoors, the fittings should be protected against direct sunlight and adverse weather conditions.

TECHNICAL DESCRIPTION AND BENEFITS

Housing: Made of Polycarbonate (PC) by co-extrusion. The housing is made in light grey (RAL7035) colour. The diffusing (upper) part is opalised. Thanks to the used raw material the whole fitting shows very high mechanical strength and high heat and shock resistance (IK08).

The co-extruded opal diffuser offers you:

– extremely high light transmissivity (up to 90%) unique on the market

– homogenous, well-balanced light dispersing (no shadows)

– elimination of the dazzling effect (no glare)

– unique appearance and clean impression (no clips, no dots of the single LED´s)

– keeping the usual, well-known features of the diffuser such as chemical and heat resistance, mechanical features, UV stabilization etc.

End caps: Made of extremely resistant polyamide and glued to the housing.

Gear tray (reflector): White powder coated steel sheet according to Zhaga standards or customized.

Electrical components: The adequate power supply is ensured through electronic driver, that is built into the luminaire.

DOWNLOAD

MOUNTING INSTALLATION

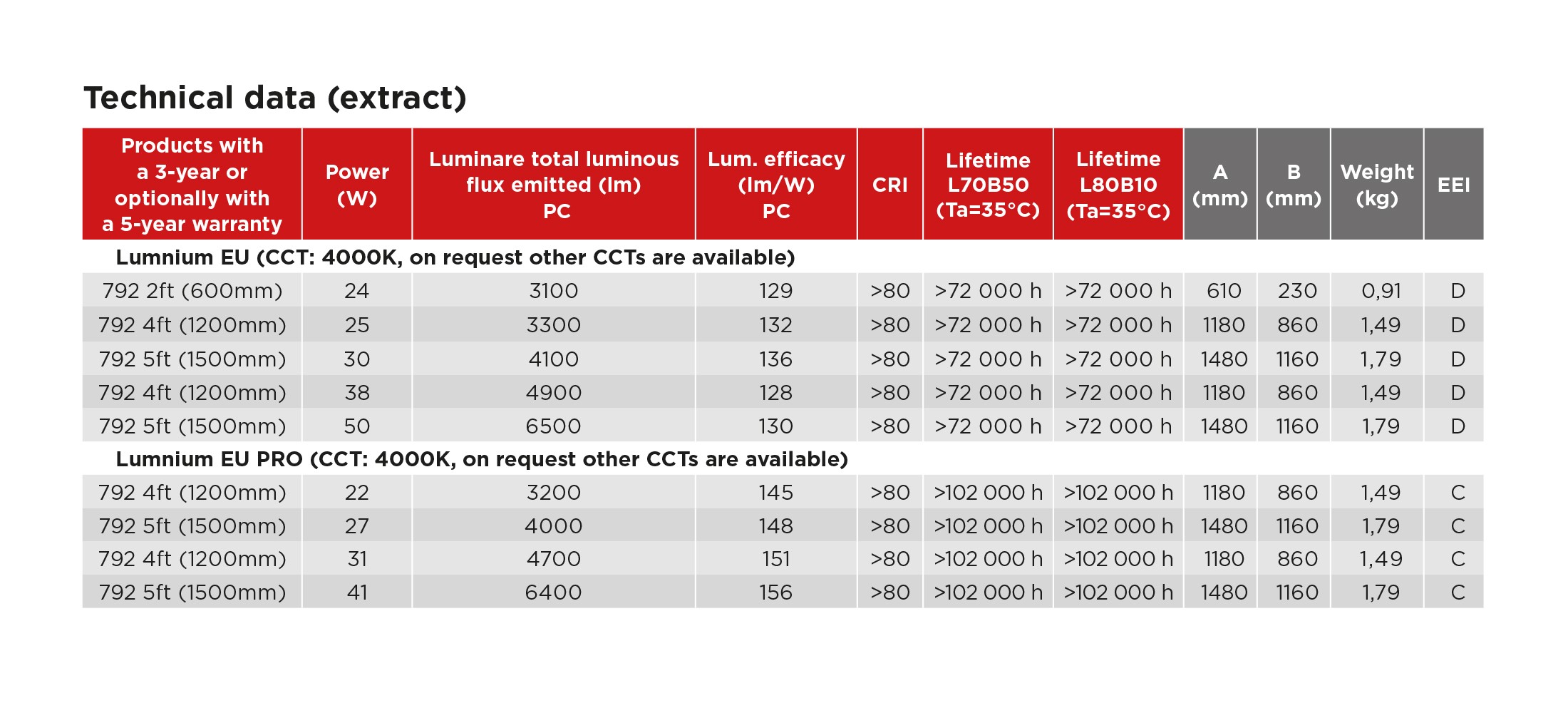

TECHNICAL DATA