COEXTRUSION

Coextrusion is a complex extrusion process in which the machine can extrude two materials of different colours at the same time (merged within the tool). Its main advantage is that the optical part of the luminaire can be clear or opalised, while the back of the extruded profile can be any other colour, usually white or grey.

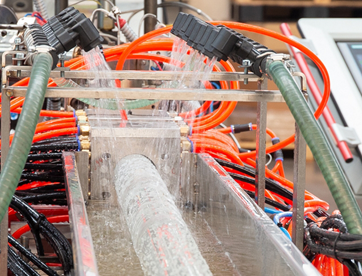

The machine has an extrusion speed of 0.8-3 m / min – depending on the construction. The raw materials we use are PC or PMMA.

In the lighting business we use it for manufacturing extruded profiles applied at tubular luminaires such as in case of our newly developed 793-Multiproof, too.

Coextrusion offers several advantages to our company as an exciting field of technology. New dimensions are opening in product development that are limited only by imagination. This resulted in the expansion of our product portfolio. We expect that the installation of the new extruder line will provide our company with further business opportunities and new target markets.