775-PCLINE

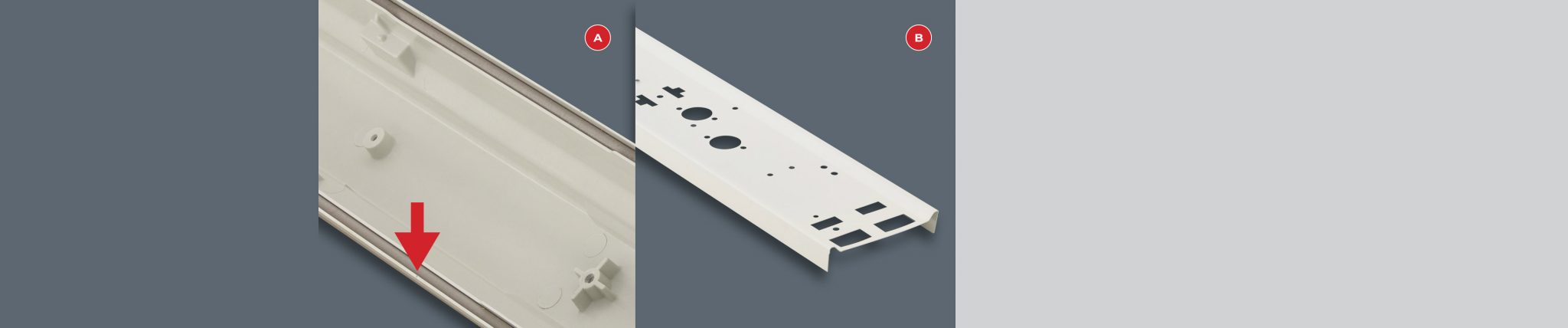

A. In order to ensure maximum chemical and weather resistance, silicon-based gasket with enhanced resistance is optionally available.

B. Universal gear tray for both, T8 as well as T5 version.

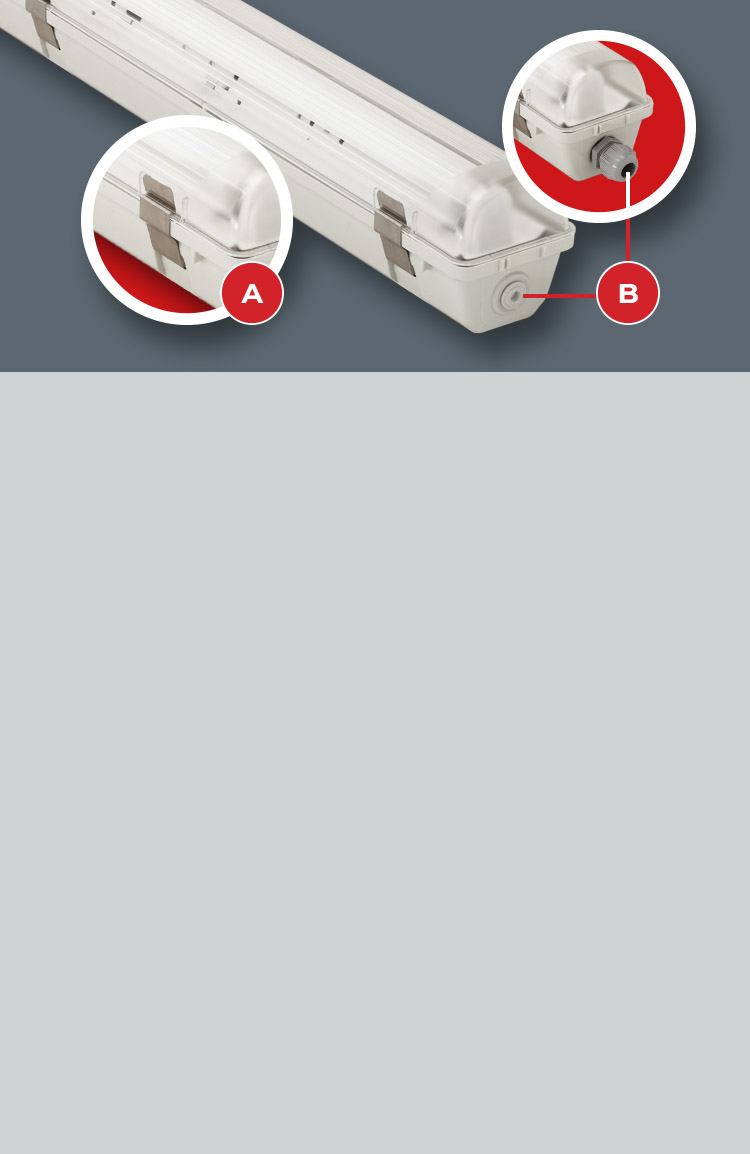

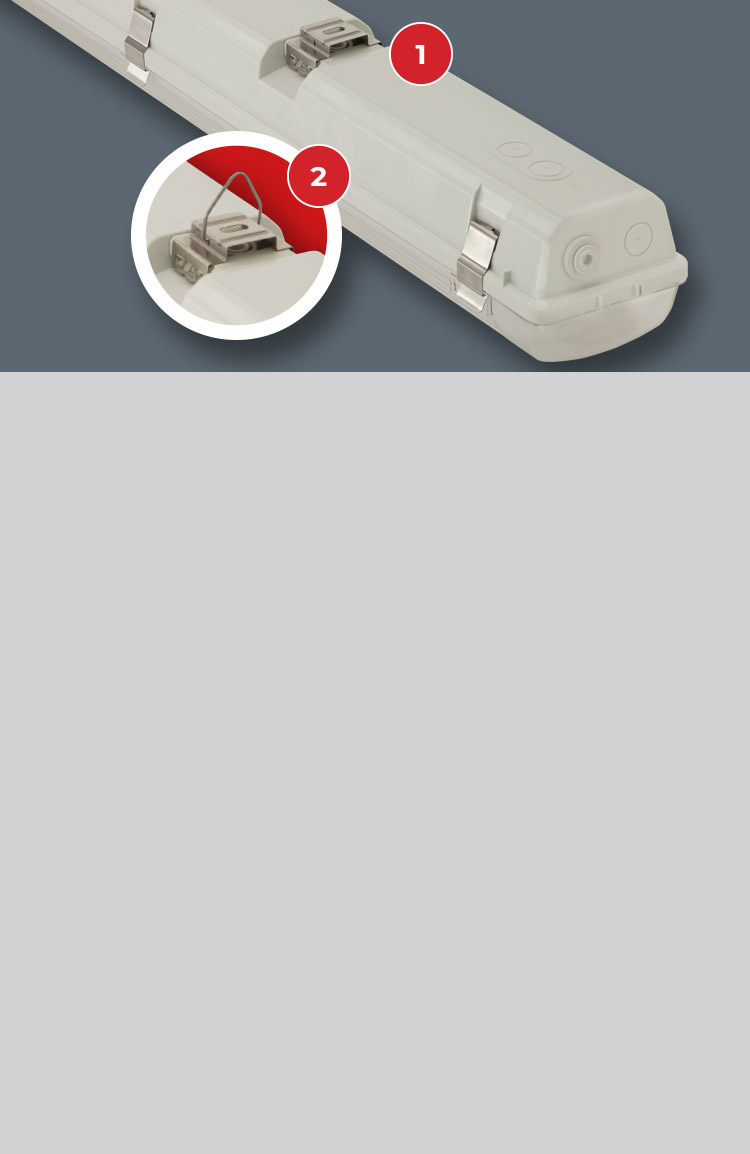

A. Fixing the diffuser to the body: with stainless steel clips.

B. Cable entry through grommets or through cable glands.

Ways of installing

1. With stainless steel suspension brackets (easy-to-install) onto the ceiling.

2. Suspension on chains with stainless steel suspension brackets mounted with hooks.

A. In order to ensure maximum chemical and weather resistance, silicon-based gasket with enhanced resistance is optionally available.

B. Universal gear tray for both, T8 as well as T5 version.

A. Fixing the diffuser to the body: with stainless steel clips.

B. Cable entry through grommets or through cable glands.

Ways of installing

1. With stainless steel suspension brackets (easy-to-install) onto the ceiling.

2. Suspension on chains with stainless steel suspension brackets mounted with hooks.

PARAMETERS

Built-in

Options

TECHNICAL DESCRIPTION

775-PC

Industrial dust and waterproof luminaires

Equipped with LED modules. 775-PC is available in the following sizes: 2x600mm, 1x1200mm, 1x1500mm, 2x1200mm, 2x1500mm

YOUR MAIN BENEFITS:

FIELD OF APPLICATION:

Due to the construction principles of gasket, closing system and diffuser our fixtures ensure a high grade of protection (IP65 or IP66) against dust, contamination, and water permeation. (Optionally available in IP67). In accordance with their IP-grade they can be used widely to illuminate spaces with dusty and humid environment. Thanks to its enhanced impact resistance, 775-PC is especially suitable for applications, where a high IK impact rating is required.

When using outdoors, the fittings should be protected against direct sunlight and adverse weather conditions. Under 0°C the application of venting cable gland is necessary, as well as silicone gasket is strongly recommended.

TECHNICAL DESCRIPTION AND BENEFITS

Housing: It is made of flame retardant injection moulded polycarbonate (PC) (suitable for 850°C glow wire test), in light grey (RAL7035) colour. This material has very high mechanical strength and allows us to reach an excellent shock resistance.

The diffuser is available in the following versions: Injection moulded polycarbonate (PC), opal, with a shock resistance of IK10, with extremely high light permeability and well-balanced light dispersing.

As option injection moulded acrylic (PMMA) diffuser in opal version is available. (not IK10)

The diffusers are designed with respect to their optical characteristics and are UV resistant.

The gasket between the diffuser and the housing is available in two versions:

– Injected silicone-based endless foam

– Non-aging PU (polyurethane) endless foam

Fixing of the diffuser to the body: with highly resistant clips made of stainless steel (standard or tamperproof).

Gear tray (reflector): White powder coated steel sheet according to Zhaga standards or customised.

Electrical components: in accordance with the requested specification suitable for LED technology, details see under technical data.

DOWNLOAD

MOUNTING INSTALLATION

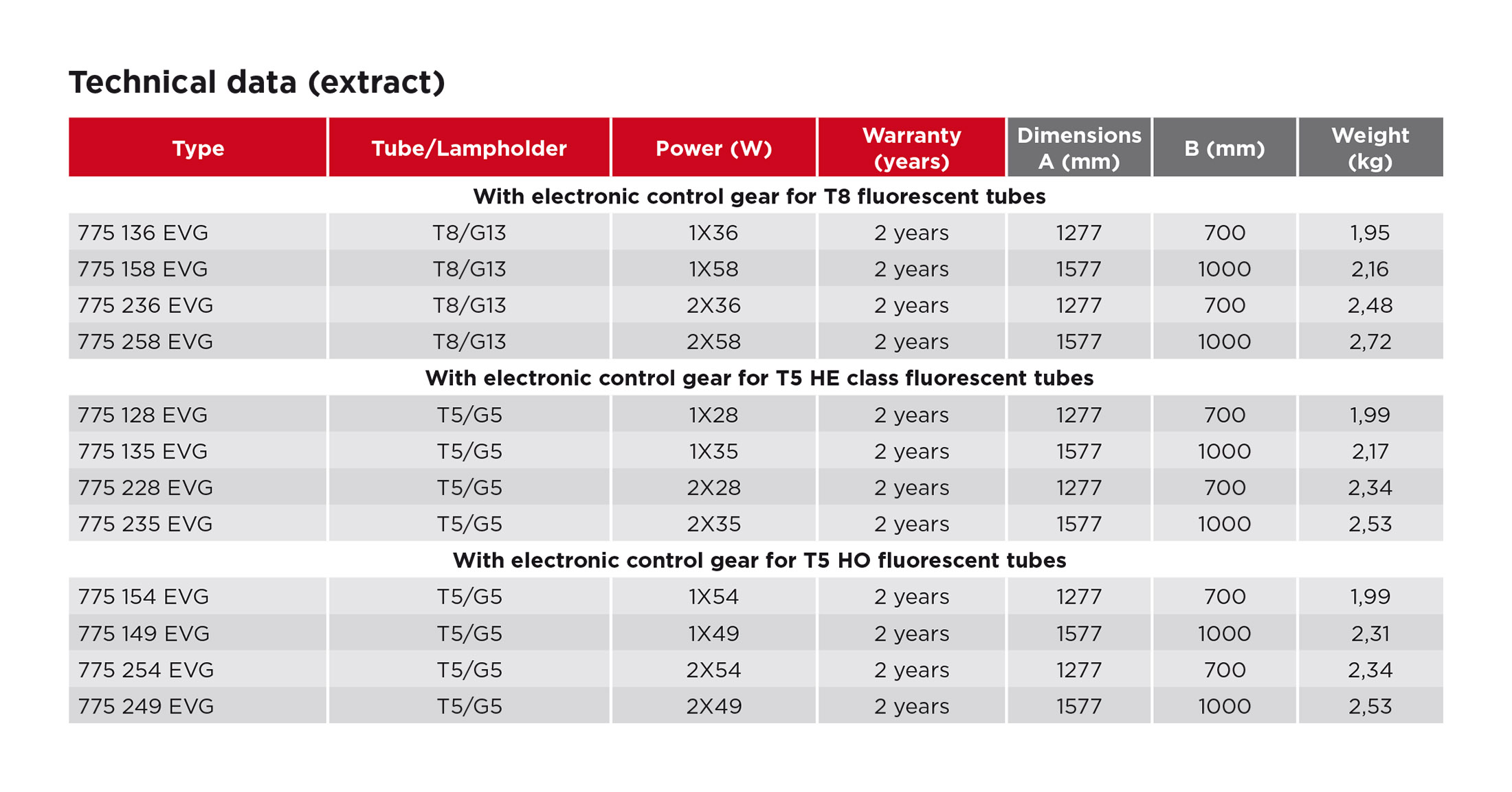

TECHNICAL DATA